Serviceable Shock Absorbers- A boon for motorcycle rider

Shock absorbers deliver important functions on a motorcycle Viz., offering a comfortable ride & required handling behavior. Almost all professional & leisure riders feel the need of customizing their shock absorbers & upgrading for better performance. The professionals & enthusiasts also need to customize the damping setting i.e., damping tuning/re-valving to match their target performance. For a majority of such upgrades, there is a need to access the shock absorber damper body which houses the piston, valves, oil & gas which generates the damping. Access to the shock absorber internal construction is also needed to replace the critical wear & tear parts like oil seal, piston ring, rubber O rings etc which usually gets worn earlier than the structural parts. Oil leakage is a very typical & a common type of failure which occurs in shock absorbers which can be repaired when the internal construction of a damper body is accessed.

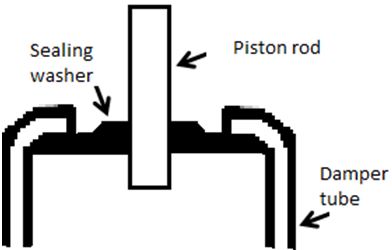

Unfortunately, the majority of motorcycles especially in India comes with a non-serviceable type of shock absorbers. Refer below image which shows the typical shock absorber where the damper tube is spun to lock the internal parts in order to function correctly. This operation of spinning the tube is of a permanent nature & irreversible. Hence any access to the internal parts like piston, valves etc cannot be done without damaging the damper tube which is a main component in the shock absorber. The reason for having this non-serviceable type of construction is that this construction allows using a small thickness/thin damper tube. Thin damper tube results in lower cost for the OEM manufacturer of motorcycle & also results in simpler design to manufacturing in large mass production volumes. The result of adopting this construction is that the rider has to discard the stock shock absorber when in need of customization. Also, the rider has to discard the shock absorber in case of oil leakage or any small failure of an internal part. Long and/or extreme usage of shock absorber results in the creation of metal sludge which contaminates the oil & also turns the oil black. The shock absorber has to be discarded for all such cases & hence the life of non-serviceable shock absorbers gets limited to 6 months-2 years depending on the usage.

Non-Serviceable Shock Absorber

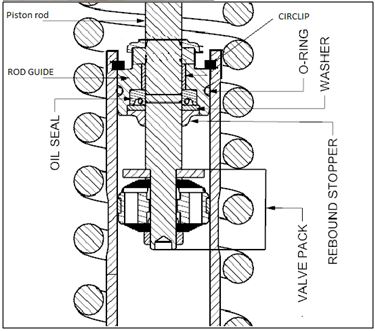

On the other hand, serviceable shock absorbers are deployed in some of the premium motorcycles like KTM, Kawasaki etc. The serviceable type of shock absorber comes with a thicker damper tube & slightly complex construction where the damper is closed using a threaded cap or a circlip. When there is a need to retune the damping forces or upgrade/replace any of the internal parts the damper can be easily opened & changes can be performed. In case of wear & tear of internal parts & in case of oil leakage the affected parts can be easily replaced & the life of shock absorber gets extended much longer as compared to a non-serviceable type. It also costs lesser to the rider to replace the required failed internal child part as compared to replacing a complete shock absorber as in case of a non-serviceable type of shock absorber.

For motorcycles which come with the non-serviceable type of shock absorber, there are much good quality aftermarket products. These after-market shock absorbers are fully serviceable & offers advanced technology options & user-friendly adjustments. These after-market shock absorbers cost higher due to their low volumes as compared to the spare part cost of stock OEM shock absorbers. However, owing to the serviceable nature the rider can get the benefit of customization of performance as well as replacement of only the required child part in case of oil leakage or wear & tear. The contaminated oil due to extreme/long usage can be refurbished & shock absorber performs as new if all wear & tear parts are replaced along with fresh damping oil. This way the higher cost of after-market serviceable shock absorber gets paid & offers better value for money. The life in such case gets limited by the structural components which can withstand even more than 3 to 5 years if serviced at regular intervals with the replacement of wear & tear parts.

Note: Damper internal construction is very complex involving many minute components & any wrong sequence of valves or placement of parts can bring a major change in performance which cannot be detected unless checked on a computerized damping force testing machine. We recommend getting such changes done either through an expert or manufacturer authorized personnel.