What should be the optimum motion ratio for ATV suspension

All terrain vehicle (ATV) is also known as quadricycle & is meant to handle a large variety of terrains which demands an optimum suspension design. ATV suspension designer considers many factors viz., damping ratio, wheel travel, bumper travel, strength requirement, packaging constraints & light weight shock absorber however the most critical is motion ratio.

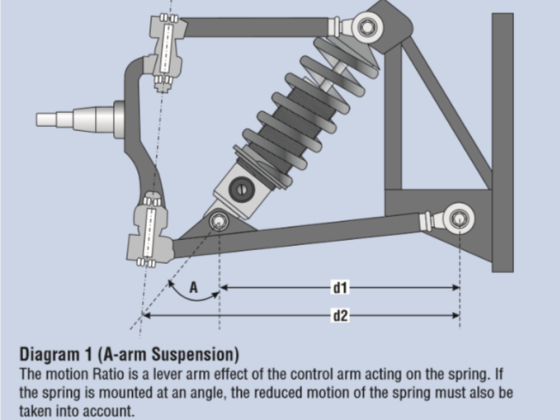

Motion ratio is simply defined as the ratio of shock absorber travel to wheel travel.

Motion Ratio = Shock absorber travel / Wheel travel

The value of motion ratio is very important to arrive at ride frequency, ride rate, wheel rate, spring rate, damping ratio, critical damping coefficient etc.

There are good reasons to keep the motion ratio higher because it helps to achieve:

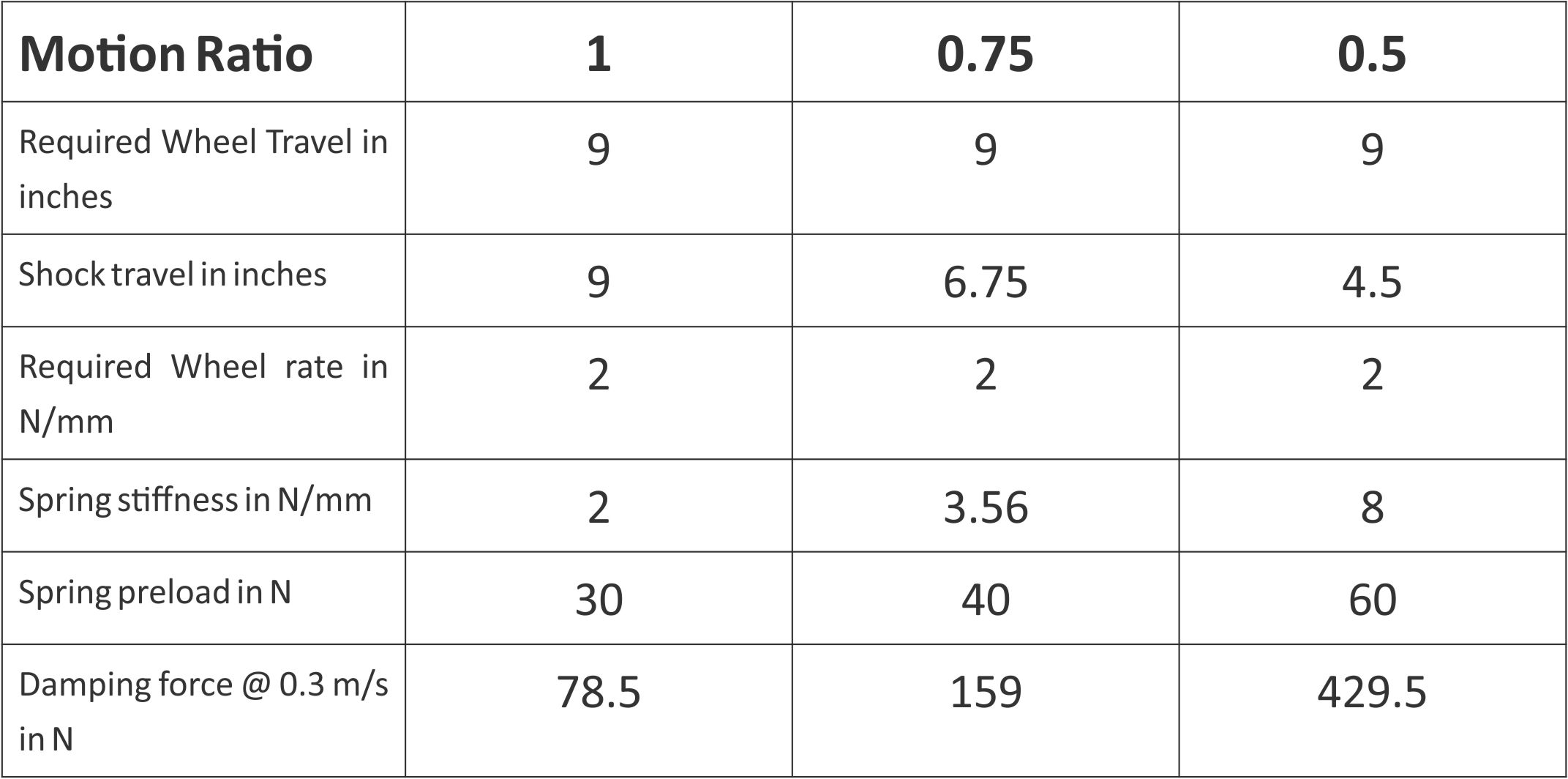

1. Lower spring rate resulting in lower weight & cost of spring

2. Compact shock absorber design for better packaging

3. Higher shock displacement & velocities. Shock absorbers give faster damping response & perform better at higher velocities.

4. Lower damping forces resulting in compact shock absorber piston.

5. Lower stress induced in shock absorber mountings

However higher motion ratio needs longer stroke of shock absorber & higher bending moments on the damper piston rod. To withstand the higher bending moments the shock piston rod size needs to be increased which in turn increases the internal pressures or damper piston size. Also it needs longer length of shock absorber. Hence maintaining higher motion ratio is not practical at many times.

Below table display the sensitivity of motion ratio on above parameters for a better understanding:

Hence it is very critical to select motion ratio such that benefits of better damper response are achieved & at the same time the practical constraints are considered.