Gas charged Shock Absorbers – What’s the entire gimmick about?

Here we present the entire truth behind the market gimmick of these shock absorbers, their need in motorcycles, their differences with conventional pure hydraulic shock absorbers & their advantages.

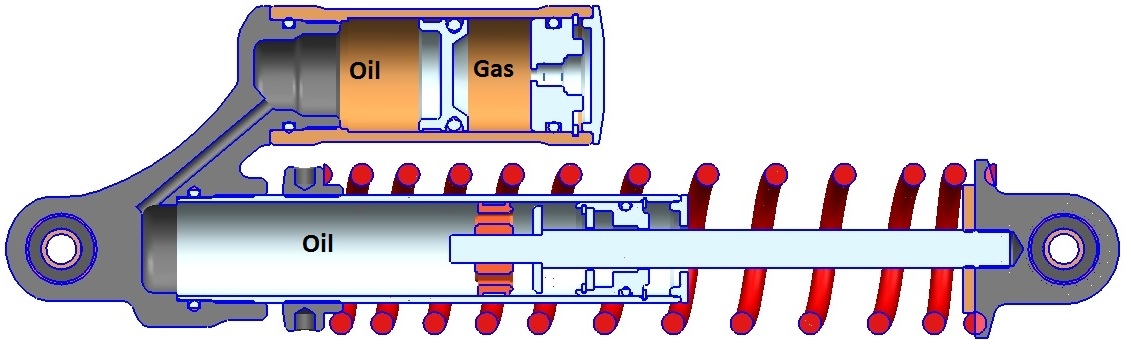

Shock absorbers deliver important functions on a motorcycle viz., offering a comfortable ride & required handling behavior. Shock absorbers achieve these functions primarily through compression spring which absorbs & release the energy and through hydraulic damper which necessarily dampens the energy. The damper component is a hydraulic piston-cylinder arrangement which offers resistance to the flow of oil through orifices across the piston & deflection of valves in the piston resulting in a conversion of kinetic energy to heat energy. A typical arrangement is shown below. Anabolic bodybuilding forum, buy steroid c Executive Technologies St Lucia buy letrozole uk weight training program without equipment.

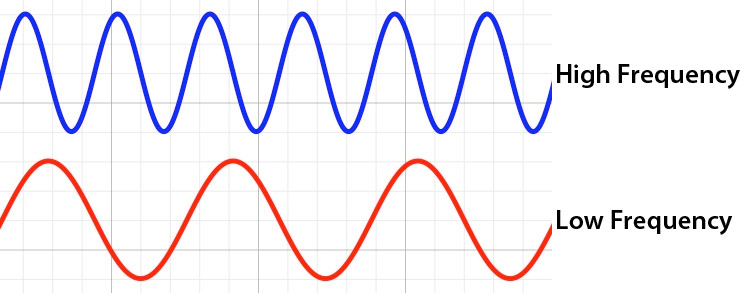

This construction is adequate for generation of damping forces when the piston movement is slow i.e., less frequent viz., up to 3 Hz (Low-frequency road input). This can be associated with large movements as well as small movements of piston. This generally corresponds to less vehicle speeds & road profiles viz., bump/pothole. In such scenario gas charged shock absorbers have nothing real to offer. However when the piston movement is quick i.e., more frequent Viz.,5~10 Hz (High frequency road input) the pure hydraulic construction starts under performing & offers serious performance issues when the piston movements reaches 15 Hz. This generally corresponds to higher vehicle speeds & road profiles Viz., rough road/highway. This can be associated with large movements as well as small movements of piston. This under performance is because oil by its nature is sluggish i.e., have high response time. During the high frequency input or quick piston movement this oil has to move across the piston in very less time which is not possible by oil alone & results in delay in generation of damping. This result in a small amount of time during the piston movement where there is no damping force generated. The absence of damping force for a small fraction of time results in loss of ride comfort, bumpy ride, loss of tire road grip & loss of handling control of motorbike. These performance issues become even more serious when it comes to higher powered bikes, road racing & extreme off road biking.

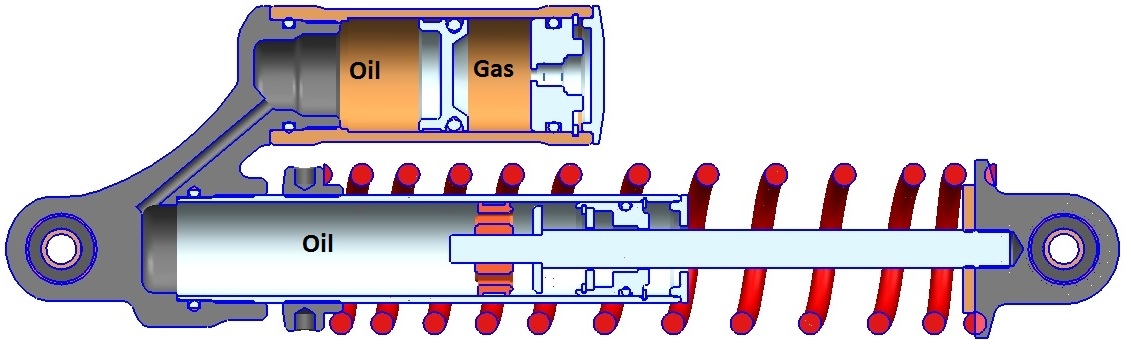

The solution comes in the form of gas charging of shock absorbers where the same hydraulic oil does the required function of damping generation however with the support of pressurized gas above the atmospheric pressure. Due to this pressure on oil its response time reduces & oil starts generating damping forces without any delay even with quick piston movement i.e., high frequency road inputs. This way the motorbike maintains the ride comfort, road grip & handling control. The gas is an inert gas like Nitrogen N2 (not truly inert) & its change in pressure with temperature is lower than air which is beneficial for the shock absorber components.

The construction of gas charged shock absorber can be either mixing of gas with oil & placing the shock absorber inverted in the motorbike so that N2 being lighter than air stays upwards & does the required function. However due to no physical barrier between oil & gas it causes the oil to mix & form emulsion which can get trapped in piston & again result in loss of damping. Recommended & robust construction includes putting a physical barrier between oil & gas either in a separate gas canister OR just below the oil in line with the piston movement. Both performs equal with the inline construction needing a higher fitment length on the motorbike.

The pressure level inside the gas charged shock absorber plays a very critical role in achieving the required performance. These pressure levels are set according to the magnitude of damping forces to be generated. If the pressure level is inadequate then the gas charged shock absorber will not perform as required & will behave equal or even worse than the pure hydraulic shock absorber. Zedling team recommends not less than 10 Bar gas pressure on twin type shock absorbers & 15~25 Bar gas pressure in mono-shock type of shock absorbers. Hence it must be noted that just the presence of gas do not necessarily makes the gas charged shock absorber perform better than pure hydraulic shock absorbers. The gas charged shock absorbers adds to the aesthetic appeal however no matter how well it is marketed the real advantage can be achieved only when it performs.